Helicopter Composite Panels

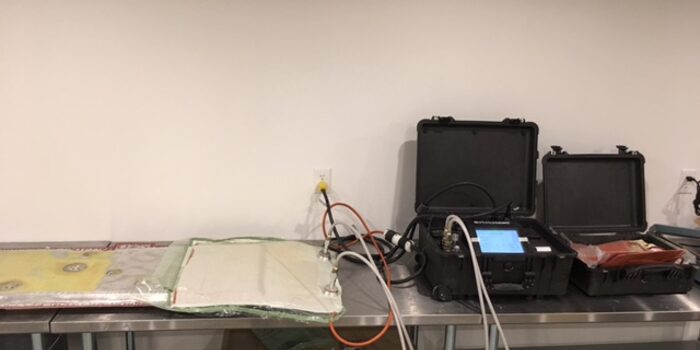

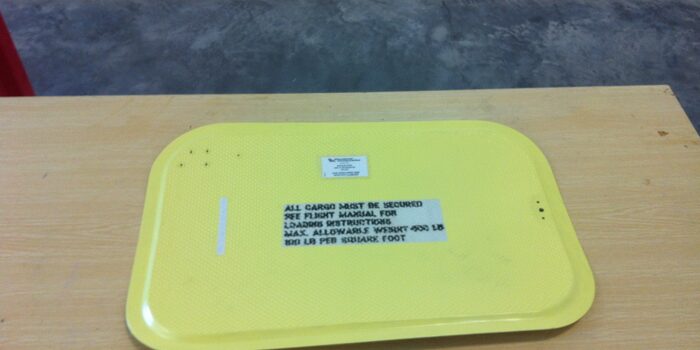

We can repair your Sheet Metal Honeycomb panels by performing a complete tear down of the panel or we can perform a spot repair with the use of our hot bonder, this can save you time and money, with out sacrificing the durability of the repair.

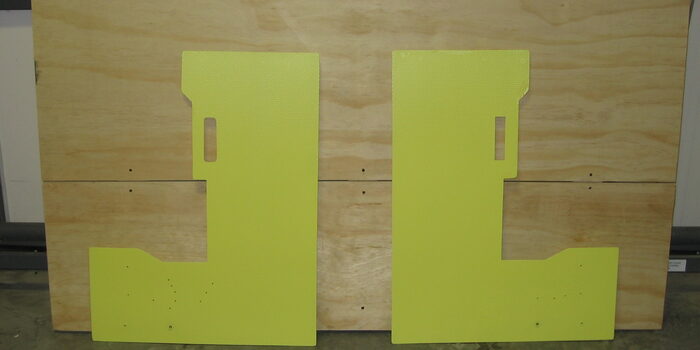

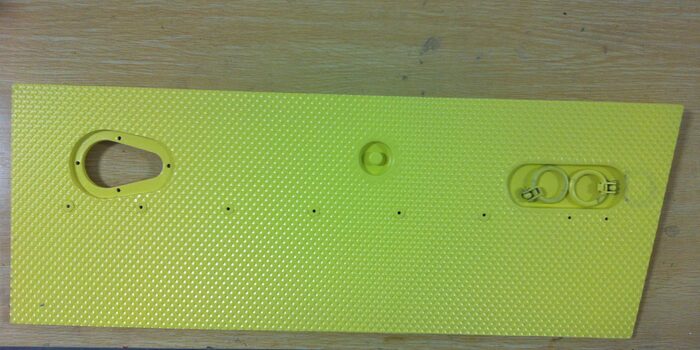

A complete tear down involves re-skin and re-core as per our engineering approvals then refinish so that they are ready for paint.

A spot repair follows the same process but we only remove the damaged section as per our engineering approvals, then we refinish so that they are ready for paint.

We are always adding new panels to the list and work closely with our Design Approval Representative (DAR) or US DER to give you the quickest possible turn times.